News

Energy Management

Paper

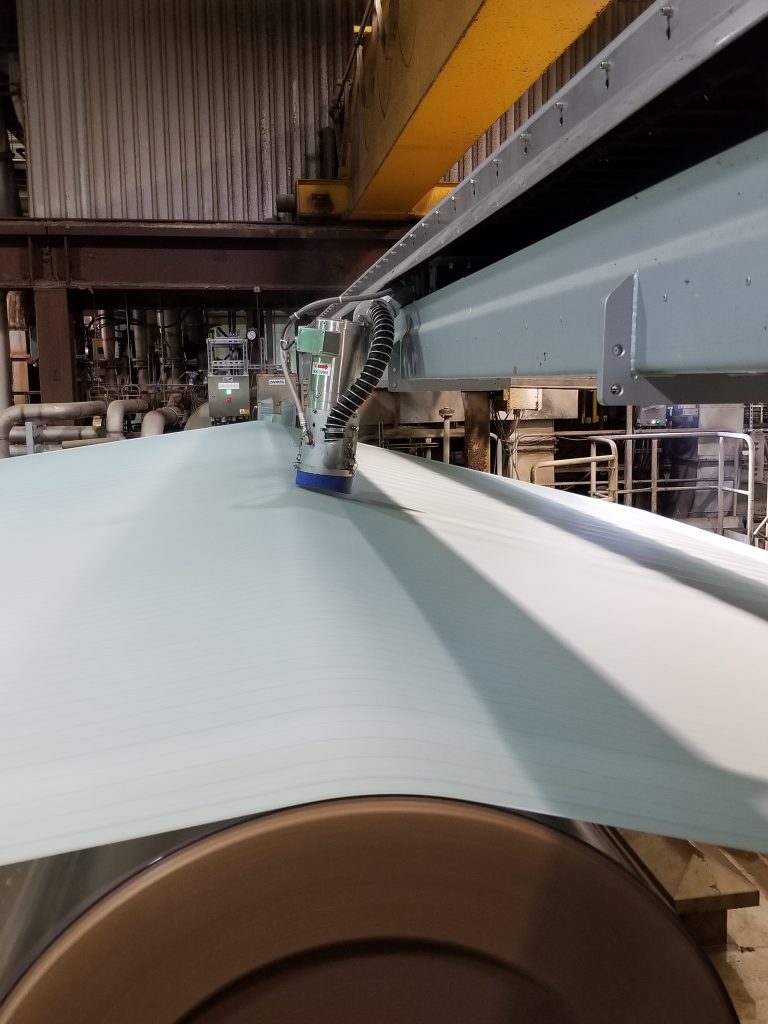

Linerboard mill sees energy savings with installation of smart cleaner system

November 18, 2019 By P&PC Staff

Coldwater, a paper machine solutions provider, recently started up its EZ eco smart cleaner system on a top former and bottom wire at a North American linerboard mill.

After 60 days in operation, the mill says the cleaning system is exceeding expectations for wire cleanliness, elimination of stickies, elimination of passivation chemical, sheet break reduction, and resulting in a significant reduction in energy/water consumption.

The EZ eco smart cleaner’s design uses traversing high-pressure rotating heads that deliver 2,200 psi (150bar) water pressure through 32 jets creating shear forces from rotation, which cleans of all types of forming wires. The 5-inch (130-millimetre) diameter head delivers twice as much coverage area in the same amount of time as a traditional oscillating shower.

This technology gets fabrics clean with less water, reducing freshwater consumption by 95 per cent. The technology also minimizes mist, eliminating the need for mist removal equipment.

The linerboard mill indicates it achieved the following benefits after 60 days of operation: A 30 per cent reduction in sheet breaks, elimination of stickie deposits on the headbox, water savings of 50 million gallons per year, energy savings of 672,000 KWh per year and CO2 reduction of 410 tons per year.

Print this page